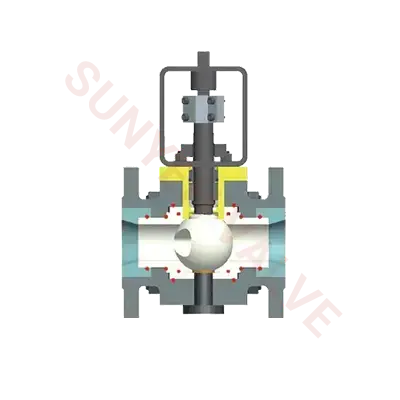

Working Principle of the Anti-abrasion Butterfly Valve

A butterfly valve is a valve used to cut off, connect, or regulate the flow of fluids in pipelines. It mainly consists of the valve body, the butterfly plate, and the driving mechanism.

Working principle: When the butterfly plate rotates around the valve body's central axis, the opening or closing of the butterfly plate changes the flow area of the valve, thereby regulating the flow of the fluid. When fully open, the butterfly plate is parallel to the valve body's passage, offering minimal resistance and allowing the fluid to flow freely. When fully closed, the butterfly plate is perpendicular to the valve body's passage, preventing the fluid from passing through.

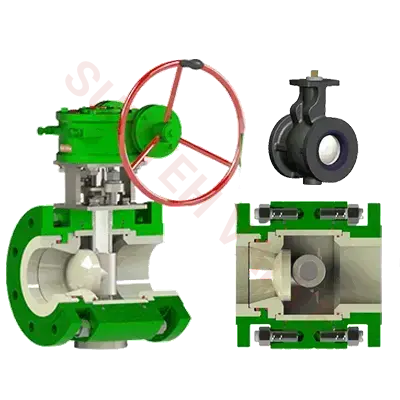

Advantages of the Anti-abrasion Butterfly Valve

The product characteristics and advantages of the anti-abrasion butterfly valve include:

Wear-resistant design: Made with wear-resistant materials, which extends its service life and reduces maintenance costs.

Good sealing performance: Ensures no leakage of the medium, meeting the requirements of various working conditions.

Simple structure: Easy to install, maintain, and operate, reducing labor costs.

Energy-saving and environmentally friendly: Low fluid resistance, which reduces energy consumption.

Wide application: Suitable for a variety of fields, including petroleum, chemical, and water treatment industries.

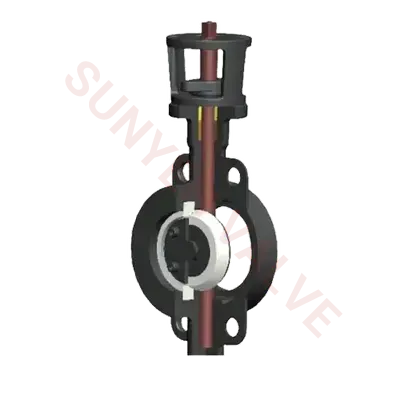

Application Range of the Anti-abrasion Butterfly Valve

The anti-abrasion butterfly valve has a wide range of applications, including:

Water treatment systems: Used in water plants, wastewater treatment plants, and drinking water treatment, enabling medium diversion, convergence, and flow regulation.

Chemical industry: Suitable for petroleum, chemical, pharmaceutical industries, used to control the flow of corrosive and toxic media.

Textile and dyeing: Used in textile and dyeing equipment to regulate the flow and direction of dyes, additives, and other media.

Food and beverage: Used in food and beverage production lines to control the flow of beverages, water, and other media, ensuring production safety.

Pulp and paper: Used in paper production lines to regulate the flow of pulp, water, and other media, improving production efficiency.

Energy industry: Used in power plants, refineries, and other energy facilities to control the flow of fuel, cooling water, and other media.

en

en  es

es  ru

ru  ar

ar  tr

tr  id

id