Ball valves, which control the flow by rotating a ball through a valve stem, are widely used in fluid control systems due to their quick opening and closing, simple operation, and reliable sealing. Among them, ball valve floating type and fixed ball valve are two common types, which differ significantly in terms of structure, working principles, and suitable working conditions, each with its unique advantages.

Ball Valve Floating Type and Fixed Ball Valve Differences

Structural Features

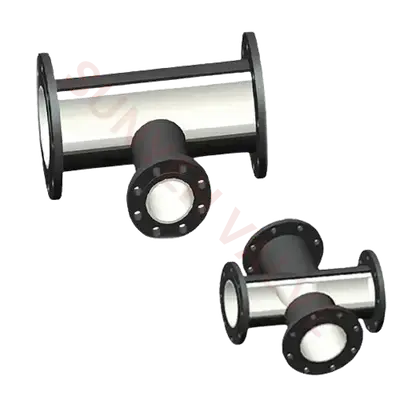

Ball Valve Floating Type: The ball floats within the valve body and is not fixed to the seat. Typically, only one lower valve stem is connected to the ball, while the upper valve stem mainly transmits torque. When the medium passes through the valve, the ball is pushed by the fluid's thrust and moves toward the outlet side, tightly pressing against the sealing surface at the outlet, thereby achieving a seal.

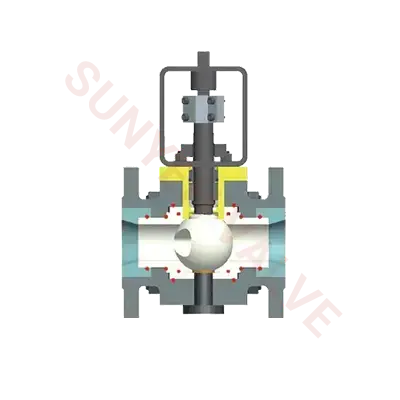

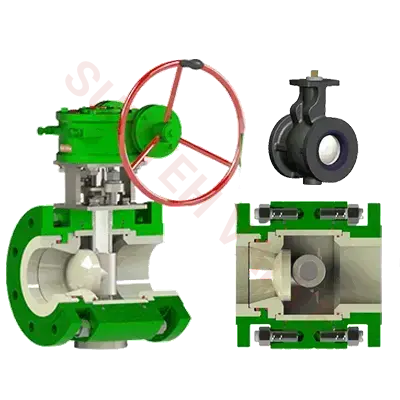

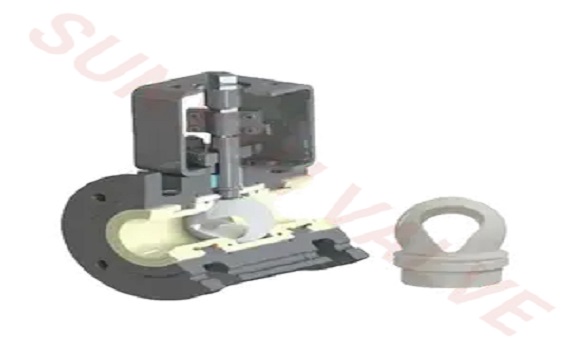

Fixed Ball Valve: The ball is fixedly connected to the valve body via the upper and lower valve stems and can only rotate around the valve stem's axis. The valve seat is movable and is pressed against the ball by the medium's pressure to form a seal. The fixed ball valve also has a fixed shaft at the bottom of the ball to limit the ball's movement.

Working Principle

Ball Valve Floating Type: It relies on the pressure of the medium to push the ball towards the outlet valve seat to achieve sealing. The higher the medium pressure, the better the sealing effect. At low pressure or with no medium pressure, the ball may not tightly adhere to the seat due to its own weight or other factors, potentially affecting sealing performance.

Fixed Ball Valve: It achieves a tight seal between the ball and the seat through the pre-tensioning force between them and the valve stem's drive. Its sealing performance is relatively stable and not affected by fluctuations in medium pressure.

Appearance Features

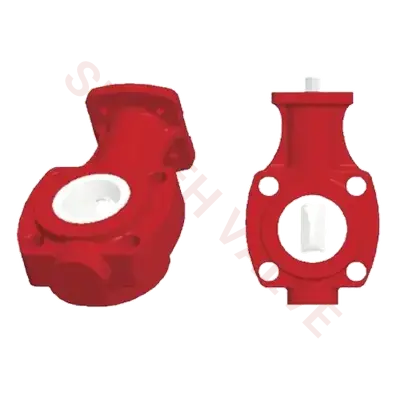

Ball Valve Floating Type: The overall structure is relatively simple, compact in shape, and usually smaller in size. Since the ball floats and does not require a complex fixed structure, the valve body is generally thinner.

Fixed Ball Valve: The structure is relatively more complex, and the overall shape is somewhat bulkier, with a thicker valve body. This is to accommodate the fixed ball structure and ensure the stability and sealing of the valve.

Advantages of Ball Valve Floating Type and Fixed Ball Valve

Advantages of Ball Valve Floating Type

Low cost: Due to its simple structure, the manufacturing cost of a floating ball valve is relatively low, making it suitable for applications sensitive to cost.

Quick opening and closing: The operation only requires a 90-degree rotation, making it simple and fast. It is suitable for situations requiring quick shut-off or fluid distribution.

Simple maintenance: With a compact structure and fewer components, maintenance and replacement are easy.

Suitable for high medium cleanliness: Since the ball floats, it can automatically adjust its fit with the valve seat, making it suitable for applications where high cleanliness of the medium is required.

Advantages of Fixed Ball Valve

High pressure resistance: The ball is fixed by the upper and lower valve stems, allowing it to withstand higher pressure and temperature, making it suitable for high-pressure, high-temperature, or corrosive medium conditions.

Reliable sealing performance: The valve seat can automatically compensate for wear under the pressure of the medium, maintaining good sealing performance for an extended period. Additionally, the sealing surfaces of fixed ball valves are typically made of high-performance materials like PTFE, further improving sealing efficiency.

Stable operation: Torque is evenly transmitted to the ball through the upper and lower valve stems, ensuring smooth rotation and uniform force on the ball, which contributes to the long-term stability of the valve.

Versatile functions: It can achieve double block and bleed, dual isolation, and other functions, enhancing the safety and reliability of the pipeline system. Fixed ball valves are also suitable for applications requiring frequent flow adjustments.

Both ball valve floating type and fixed ball valve have their advantages and disadvantages. The choice between the two types should depend on specific application requirements and working conditions. Floating ball valves are ideal for low-pressure, small-bore applications where high medium cleanliness is required, while fixed ball valves offer better advantages in high-pressure, large-bore situations with high demands for sealing performance and flow control. By choosing and using the appropriate Sunyeh ball valve, the normal operation and safety of fluid control systems can be ensured.

en

en  es

es  ru

ru  ar

ar  tr

tr  id

id